Abrasive

Blasting

Empire Air Blast Systems

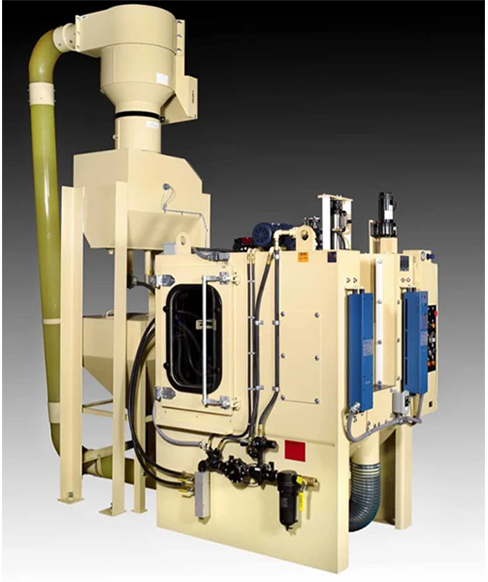

Buffalo Manufacturing is the leading distributor of Empire abrasive blasting equipment, parts and systems. Empire has been designing and manufacturing abrasive blasting equipment for over 50 years. Today, Empire manufactures the most extensive lines of blasting finishing products in the country.

Manual Blast Cabinets

Pro-Finish® systems offer perfect combinations of equipment performance and the versatility of modular designs. Backed By The Best Warranty In The Industry: Three Years Limited!

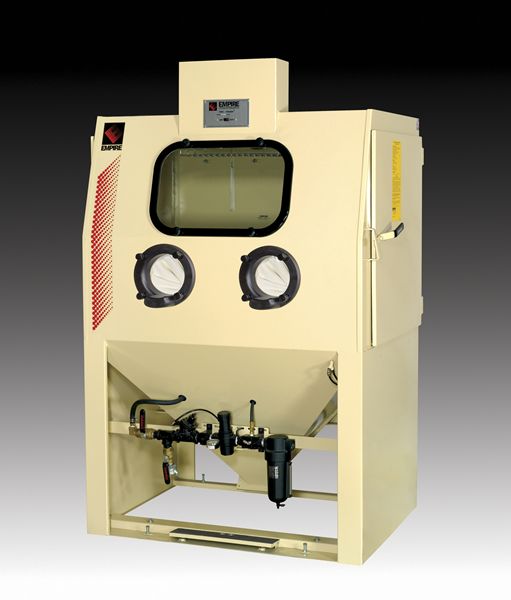

Standard Pro-Finish® Cabinets

With an off-the-shelf Pro-Finish cabinet, you get a tunable media reclaimer, a dust collection system, your choice of pressure or suction powered blast, and many other standard features. In addition, you can select from a wide range of in-stock factory options to meet your particular finishing requirements. If you need a powered or manual turntable, gun oscillation, additional blast guns, timer packages, special electrical, extended wear components or a vertical door, we can provide this equipment and other options without custom modifications.

Built-in System Components:

- Dust Collector

- Tunable Reclaimers

- One-cubic-foot Pressure Vessel

- One-cubic-foot Suction Hopper

Empire Cabinets are Available in a Variety of Configurations Suitable for Your Individual Blast System Needs:

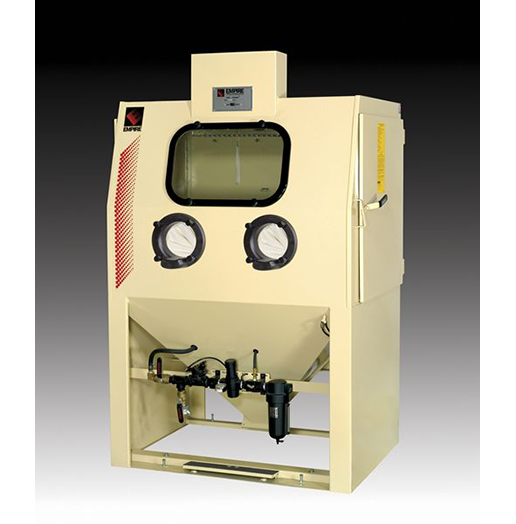

Pro-Finish® Blast Cabinets

With an off-the-shelf Pro-Finish cabinet, you get a tunable media reclaimer, a dust collection system, your choice of pressure or suction powered blast, and many other standard features. In addition, you can select from a wide range of in-stock factory options to meet your particular finishing requirements. If you need a powered or manual turntable, gun oscillation, additional blast guns, timer packages, special electrical, extended-wear components or a vertical door, we can provide this equipment and other options without custom modifications.

ProFormer™ Blast Cabinets

Empire ProFormer™ cabinets put it all together in a single assembly that’s easy to move and simple to hook up. These cabinets require only two connections, air and electrical, and include features offered in our high production Pro-Finish® line. Plus, they come in two sizes: the 3642 with interior working dimensions of 36 inches deep by 42 inches wide by 48 inches high and its bigger brother, the 4652, with working space of 46 inches by 52 inches by 48 inches.

FaStrip® Blast Cabinets

Empire’s FaStrip® cabinets provide a safe, efficient alternative to chemical stripping and cleaning of parts. Designed specifically for use with plastic media, FaStrip cabinets strip coatings from metallic and composite materials quickly and thoroughly without adverse effects on substrates. Materials on which these plastic media cabinets create the necessary etch for superior bonding of new coatings include Alclad and anodized aluminum, titanium, steel, Kelvar, fiberglass, carbon graphite and magnesium.

SafeStrip™ Cabinets

Empire SafeStrip™ cabinets contain the blast process during the cleaning and stripping of delicate surfaces. They are designed to work in conjunction with our SafeStrip portables as well as other pots capable of delivering fine media.

With a SafeStrip system, you can quickly and safely remove old coatings, dirt, oil, corrosion and other unwanted residues from soft metals, rubber, plastics and other sensitive surfaces. SafeStrip is ideal for work on tools, machine parts and molds, and in many other applications requiring a “light touch”. SafeStrip systems assure even flow of light media by creating a differential between the pressure vessel and blast pressure. This pressure differential, which can be adjusted precisely with a manual valve, prevents bridging and produces consistent feed rates.

Ergo-Blast Cabinets

Ergo-Blast cabinets accent the scope of Empire’s Pro-Finish® line, the world’s most rugged, reliable and versatile blast-cabinet system. By focusing on operator performance, Ergo-Blast cabinets give manufacturers an edge in many hands-on processes.

Designed for sit-down blasting, these ergonomic cabinets include a padded armrest, an elevated foot rest for treadle control, top-entry piping for less arm stress, a sound dampener to reduce noise and a front mounted pressure regulator – all aimed at improving operator comfort and performance during long, repetitive blast cycles.

In addition to supporting operators, Ergo-Blast cabinets include all Pro-Finish® features, such as a tunable media reclaimer which adjusts to recover a wide range of abrasives. You also have the choice of a pressure or suction blast system, three methods of dust collection, and many options to fit your specific application.

Basket Blasters - BB2 & BB4 Basket Blasters

Empire’s BB2 and BB4 Basket Blasters automate cleaning, peening and finishing of small workpieces. With certain types of parts, no other finishing method can compare to these heavy-duty production machines in terms of speed and quality results.

Operation is simple: Load parts into the unit, set the precision timer, and the Basket Blaster does the rest. By tumbling parts within abrasive blast streams, these machines deliver consistent finishes – automatically.

Empire’s heavy-duty Basket Blasters feature an unloading chute to speed parts handling and a polyurethane-lined media reclaimer supported by rugged ductwork to reduce maintenance requirements.

Basket Blasters - BBO Basket Blasters

If you’re looking for a fast, efficient, economical method for finishing small parts, check out one of Empire’s BBO Basket Blasters. To finish parts, you simply drop them into the BBO’s nine-inch by nine-inch basket, set the time, and let these table-top work savers do the rest. As parts rotate through an abrasive blast stream, they are cleaned, peened or finished evenly and automatically. By varying air pressure and abrasive media, you control the type of finish as well as required processing times.

Beyond freeing you from the tedious chore of processing parts manually, Empire’s BBO Basket Blasters save you time and money in other ways. They are inexpensive, come fully assembled and ready to operate, require only a two-horsepower compressor, use less electricity than a 150-watt light bulb, and meet OSHA requirements.

Econo-Finish® Blast Cabinets

Empire’s inexpensive Econo-Finish® blast cabinets feature a unique front-access door to simplify loading of parts, save floor space and speed finishing operations.

Designed for light-to-medium cleaning and surface finishing jobs, these economical cabinets combine sturdy, 14-gauge steel construction with the features you need to perform a wide range of finishing tasks. All Econo-Finish cabinets are equipped with a foot-treadle blast control for ease of operation, an external media regulation device, quick-change safety glass and a dust-collection system.

In addition, you can select from upgraded features such as production-quality blast guns, a pressure regulator with gauge, long-life blast nozzles and a high capacity dust collector that extends operating intervals between clean-outs. Our DC-16 and DC-30 dust collectors feature a cartridge filter with 16-gallon and 30-gallon dust capacities and built-in silencers.

Econo-Finish cabinets are available in two basic configurations: models with two-piece, swing-down and flip-up doors for maximum interior access and an even more economical unit with a swing-down door only. Models with two-piece doors can be specified with a standard upgrade package designed to extend usage and maximize production.

Continuous-Belt Air Blasters

Empire’s Continuous-Belt Air Blasters process multiple parts with the speed and economy of our Basket Blasters while expanding the envelope of tumble blasting from nuts and bolts to heavier work pieces.

Our CB-3.5 machines, available with either pressure or suction blast systems, automate cleaning, peening, deburring, profiling, finishing and many other surface conditioning tasks. Plus, they handle a vast range of parts formed from casting and injection molding, as well as the molds used to produce the parts. Often, no other finishing method can compare to these heavy-duty production machines in terms of speed and quality results.

Operation is simple: Load parts onto a rugged perforated belt, set the precision timer, and the CB-3.5 does the rest. By tumbling parts within multiple abrasive blast streams, these machines deliver consistent results automatically.

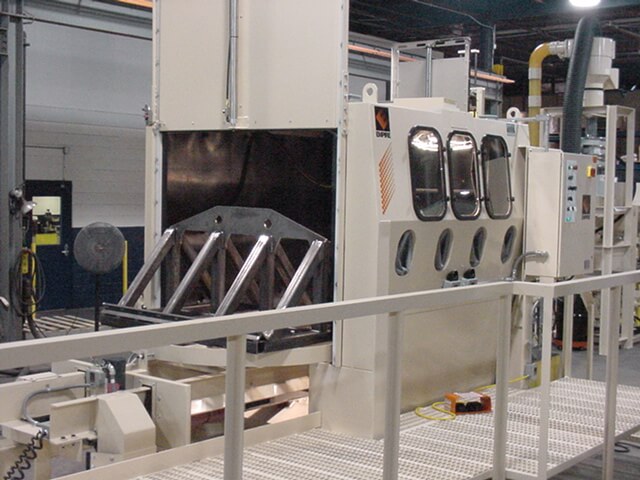

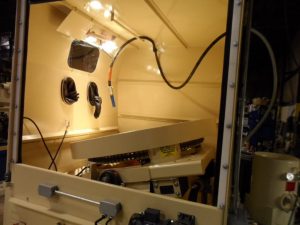

Manual Blast Cabinets with Custom Modifications

Empire’s Modified Pro-Finish® Cabinets… an economical approach to specialized finishing and surface preparation.

If your application is highly specialized, you can take advantage of the benefits of a Pro-Finish system. We can economically tailor a cabinet to meet your specific needs and reduce lead times over custom engineered purpose-built equipment.

Empire Modified Pro-Finish® Cabinets are re-engineered to meet individual work piece and process requirements.

If you are confronted with a unique application or want to accelerate production rates through partial automation, Empire can meet your needs. Empire has created hundreds of modified cabinets to satisfy focused customer needs in a wide range of industries.

Work Envelope Expansion

Crane Slots

Pass-through Cabinets

Entrance and Exit Vestibules

Heavier Weight Cabinets

Dual-cabinet Systems

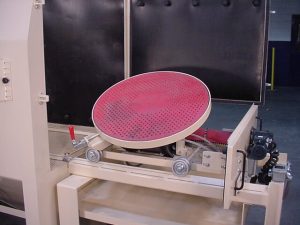

Powered Turntables

Powered Work Carts

Tilting Work Carts

Powered Doors

Multiple Glove Locations

Roll Blast Systems

Vibratory Screeners

Larger Pressure Vessels

Powered Lance

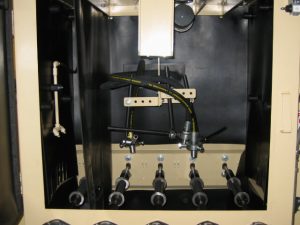

Blast-gun Oscillation

Programmable Controls

Belt Conveyor

Roller Conveyor Systems

Automated Air Blast Systems

Buffalo Manufacturing’s suite of Empire automated air blast systems range in sophistication, from standard automation to advanced robotic nozzle, part manipulation and part handling.

The ever-changing demands of manufacturing, coupled with the realties of contemporary labor shortages, make programable, automated blasting systems an optimal choice. Our customers report productivity gains between 100 and 700 percent, in additional to saving time and money, and conserving shop floor space.

All systems can be controlled to the degree your process requires with:

-

Media Flow Controls

-

Air Pressure Controls

-

Media Recovery and Classification Systems

-

Process Validation and Reporting

-

Speed Controls

Indexing Turntable Machines

This programmable, indexing turntable machine reduces per-unit cleaning costs on piston rebuilds by over 30 percent compared to previous methods.

By coordinating the movements of 16 blast guns, oscillating vertically and horizontally, with spinning work stations on a rotating platform, the system ensures thorough coverage and fast cleaning in a single pass.

Eight guns oscillating vertically clean the sides and skirts of the pistons. The guns sweeping horizontally clean tops and interiors.

Batch Processing Machines

Our batch processing systems, which include both continuous and indexing turntable machines, are ideal for parts requiring long blast cycles. In the typical work scenario, the operator loads work pieces onto the turntable, sets the timer, starts the machine and returns when the cycle is completed.

By adding a blowoff manifold and timer, which automatically remove residual material from the part and turntable, the operator is freed from the often dusty task of manual blow-off.

Continuous Processing Machines

Turntable and in-line machines for continuous processing. These systems can be loaded and unloaded manually, equipped with robotic arms or designed as an integral part of the production line.

Our continuous turntable machines come in four standard models with table diameters ranging from 36 inches up to 108 inches. Larger units are available with two rotary blast heads. The heads can be oriented to perform separate functions, such as blasting the interior and exterior of parts at the same

time. Standard features include a rubber cabinet lining and a urethane coating on the turntable for extended service life.

Single Piece Flow Cell Machines

Single-station cell machines serve as just one example of how we meet the ever-changing demands of manufacturers worldwide.

Our line of Empire cell machines reduce inventory requirements and conserve floor space, giving many customers the winning edge in an increasingly competitive global marketplace.

Rotary Head Blast Systems

Rotary blast head systems deliver tremendous coverage while conserving compressed air.

When the application calls for it, a rotary head will outperform any horizontal-nozzle oscillator, reducing the number of blast guns and energy required for the job. Our suite of Empire rotary heads contribute to the outstanding performance of our in-line conveyor, continuous turntable and batch turntable machines.

Shot Peening Systems

Air-blast peening systems with advanced computer-control, blast-coverage and material-handling features that not only increase productivity, but also assure repeatability—a major concern in these quality-intensive applications affecting the structural integrity of critical components.

In-line Systems

As with other Empire Abrasive automation systems, In-Line blast systems are available in a variety of configurations.

Final design being influenced by part size, weight, shape and material handling requirements. These systems can be as simple as a flat belt, split belts, or a roller type while more sophisticated systems are built with horizontal or vertical pinch belts.

Custom Automation Systems

Custom-component Empire automated systems are available for your specific application. Final configuration/design being influenced by part size, weight, shape, production rates and material handling requirements. No matter what your application demands – from cable blasts, to tumble blasts, to mold cleaning, Buffalo Manufacturing can custom engineer a system to fit your process and production requirements.

Gibson Wheel Blasting Equipment

Wheel blasting is another method of cleaning and preparing surfaces that does not rely on compressed air or other propellants. Instead, blasting media is fed into the center of a rapidly spinning wheel. The wheel creates a centrifugal force, which throws the media at the material, powerfully blasting its surface.

Gibson has been a trusted partner in the wheel blast equipment industry for 18 years, and Buffalo Manufacturing is a proud authorized distributor of Gibson’s equipment.

Pipe Blast Systems

Gibson Monorail Blast System

- Like the roller conveyor blast system, the monorail blast system Is designed to deliver consistent results during constant production, is used to blast heavier parts at a high volume and can be incorporated into an existing production line. This system can automate your operation, effectively mitigating high labor costs typical of most batch-type blasters.

- Systems come in different blast envelopes and with multiple blast wheels and horsepower.

Wire Mesh Belt Blasters

Dual Chamber Spinner Hangers

- Not every part is the same, so it follows that not all parts can be cleaned the same way, and fragile or irregular parts often need special treatment that can’t be provided by regular methods of automated finishing. Spinner hangers are the perfect solution for batch blasting unconventional or fragile parts and are demonstrated to improve quality and efficiency during cleaning, peening, prepping and finishing.

- These systems are simple to operate and have an easy installation process, They’re built to deliver consistent results cycle after cycle while working around the clock in a multishift production operation.

Hanger Blast Systems

Wheel Blast Tumblers

Smaller units contain either wheel or air-blast systems, depending on your needs, and can accommodate a wide array of media. They fit conveniently into cell stations or other productions that work with batch processing.

Roller Conveyor Blast Systems

- This fully-automated system is built to deliver consistent results in a non-stop line of production and is used for blasting heftier pieces at high rates. It can be easily incorporated into an existing production line. When used with another machine, Gibson’s roller conveyor blast systems can become part of a totally automated process that mitigates the high labor costs normally tied to batch-type blasters.

- Systems come in different blast envelopes and with multiple blast wheels and horsepower.

- Skew roll (also known as inclined v-shaped rollers)

- Designed to clean pipe or other long, round material.

- Billet blast systems

- Desidgned to descale and derust billet

- Roller conveyor typical applications

- Mill scale removal

- Structural steel

- Paint preparation

- Profiling

- Inspection

- Skew roll (also known as inclined v-shaped rollers)

- They’re able to be specified with either suction or pressure blast systems. Available in seven sizes and equipped with standard features proven to lower operating and maintenance costs.

Dust Collectors

- Photohelic gauge

- Magnehelic gauge

- HEPA filters

- After filters

- Silencers

- Abrasive resistant inlets

- Reverse pulse

- Rotary air locks

- Explosion vents